FEDC 3D Printing Resources:

WHAT IS THE DIFFERENCE BETWEEN LOW FIDELITY AND HIGH FIDELITY PRINTING?

Low Fidelity machines offer a quick and low-cost way to test the functionality of your ideas. High Fidelity machines can produce fully finished and functional parts ready for use. There is great overlap between the two categories, and much depends on the need of the customer and the usage of the part. Typically, higher fidelity machines better control the printing environment leading to more robust and accurate parts, but come with additional expense.

Low Fidelity

WHAT LOW FIDELITY MACHINES ARE AVAILABLE?

The FEDC has approximately twenty Low Fidelity machines available for prototyping. All are FDM-style machines that extrude plastic filament through a heated nozzle to build the part layer by layer. All use breakaway support made from the model material. The primary material is PLA, but some machines can also use ABS, PETG, TPU, Nylon, etc.

A list of these machines can be seen below:

- Ultimaker S5 – (330 x 240 x 300 mm) – primarily PLA

- MakerBot Method X – (190 x 190 x 196 mm) – primarily ABS

- BambuLab X1C – (180 x 190 x 196 mm) – primarily PETG and TPU

- CreatBot F430 – (400 x 300 x 300 mm) – primarily ABS, ULTEM 9085

- Dremel 3D45 – (255 x 155 x 170 mm) – primarily used as backup printers

For low fidelity printing, which is better: ABS or PLA?

In most low fidelity 3D printing, the printers cannot maintain a stable heated chamber. Because ABS has a high thermal shrinkage rate, layer delamination and part failure or serious degradation very often occur, especially in larger parts. PLA does not suffer from this issue, and prints great in this unstable environment. Most of the time, a part printed in PLA will perform equally or better than one printed in ABS. The main exceptions being exposure to UV or high temperatures: PLA may not perform well in those extreme conditions.

High Fidelity

WHAT HIGH FIDELITY MACHINES ARE AVAILABLE?

The FEDC has several types of High Fidelity machines available. They are described in detail below.

FDM-STYLE HIGH FIDELITY MACHINES

FDM-style machines extrude plastic filament through a heated nozzle to build the part layer by layer. The Stratasys machines use a soluble support material that can be dissolved away, whereas the Essentium machines use breakaway support made from the model material. Materials available are ABS, ASA, PC-ABS, TPU 92A, ABS-CF10, HTN, and PCTG.

A list of these machines can be seen below:

- Stratasys F370 – (355 x 254 x 355 mm) – primarily ABS, ASA, PC-ABS, but also have ABS-CF10, TPU, TPU 92A and ABS-CF10

- Essentium HSE 180-S – (690 x 500 x 600 mm) – primarily HTN and PCTG material

- Stratasys F770 – (1000 x 610 x 610 mm) – primarily ABS and ASA

POLYJET-STYLE HIGH FIDELITY MACHINES

Polyjet-style machines spray micro-droplets of photopolymers that are cured with UV light to build the part layer by layer. Our Stratasys J55 can hold and print up to five materials simultaneously in layers 18.75 microns thick, including a soluble support material that can be dissolved away. Materials available are the acrylic-like VeroColor suite, VeroClear, DraftGrey, VeroContact, and rubber-like Elastico.A list of these machines can be seen below:

- Stratasys J55 – (140 x 200 x190 mm) – primarily VeroColor, Clear, DraftGrey, VeroContact, and Elastico

SLA-STYLE HIGH FIDELITY MACHINES

SLA-style machines cure resin with a light/laser beam to build the part layer by layer. The Formlabs Form 2 prints in layers 25-100 microns thick, and uses breakaway support made from the model material. Materials available are Grey and Clear, with different engineering-grade materials to be made available upon demonstrated need.

A list of these machines can be seen below:

- Formlabs Form 2 – (145 x 145 x 175 mm) – primarily Grey and Clear

Service Request – 3D Printing

My file is too big to upload into the FEDC Service Request 3D printing form. What do I do?

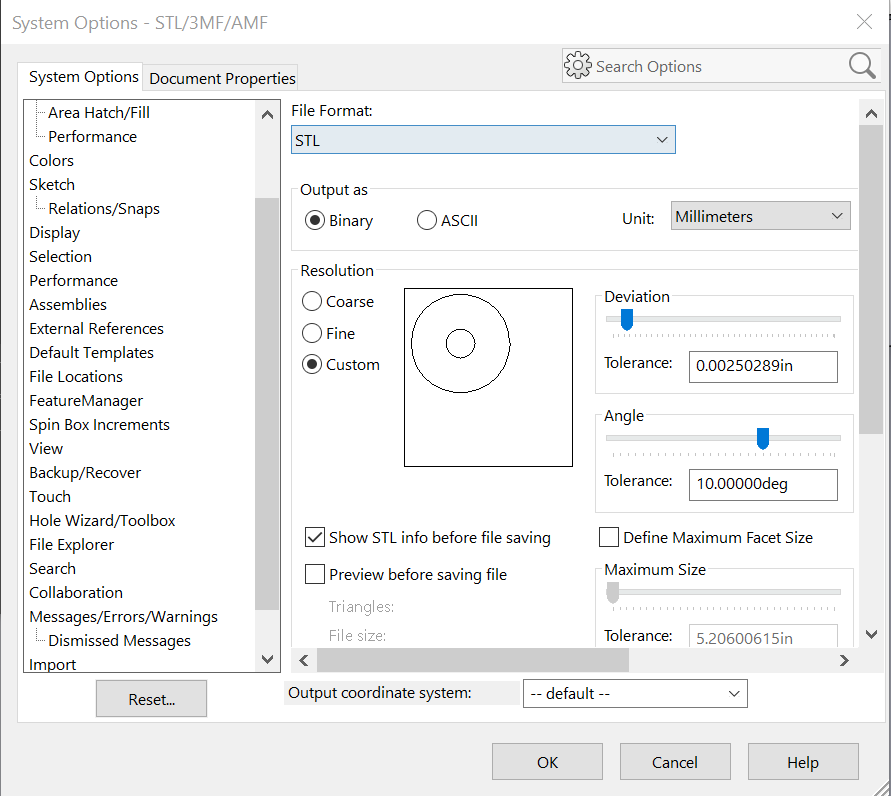

In most cases, you will need to adjust the resolution of your part as it is converted to a .stl format. In SolidWorks, this can be done by choosing Save As, select STL as the file type, then clicking the “Options” button below. Then you can adjust the Resolution Deviation and Angle to yield an acceptable part file that is not too big to upload.

https://www.cati.com/blog/2016/06/exporting-stl-files-from-solidworks-for-3d-printing/

https://help.solidworks.com/2012/english/SolidWorks/sldworks/HIDD_STL.htm

For some High Fidelity 3D printing requests, a larger file size (or even different file type) may be required to yield an accurate part. In this case, please email [email protected] for specific instructions. Be sure to include whether it is an Academic or Research project, printing/material needs, and anything else that may help us to help you.

My file upload failed stating “Sorry, this file extension is not permitted for security reasons”. What do I do?

SolidWorks

Please try the following:

- Open the SolidWorks File

- “Save As”

- “Save as type:” STL (*.stl)

- “Options” under the save as type

- “File Format” – “STL”

- “Output as” – “Binary” “Millimeters”

- “OK”

- “Save”

What is a Bounding Box/Boundary Length?

A Bounding Box of a 3D Model is the smallest rectangular prism which the model could fit into. Basically, it is the length, width and height of an object.

Why does the FEDC need a bounding box?

STL files, the 3D model format used in 3D Printing, only contain the surface geometry of a model. So, important information like color and scale aren’t stored. This can be problematic if, for instance, a part was modeled and then exported to the STL format in inches. Slicing software assumes the file’s units are in millimeters, and thus the hypothetical part would be 25.4 times smaller than it should be. Without the dimensions of a bounding box, we would have no way to know if the part is scaled correctly or not.

How do I find the bounding box of my part?

SolidWorks

In a part document, click Insert > Reference Geometry > Bounding Box

In the Bounding Box PropertyManager, select Best Fit.

Then, to view bounding box’s dimensions, click File > Properties > Configuration Specific

Fusion 360

In the Browser tab, right click the name of the part, then select Properties. A menu will pop up on the right side of the screen. Click Physical > Bounding Box.

Online 3D Viewer

In https://3dviewer.net/ upload an STL to view sizes of model details of the part.

What is the cost of 3D printing my part?

Each style of printing and material comes with different pricing, so this is no easy answer. For Academic requests we only charge for the raw printing materials. When printing within your FEDC allotment, we also apply discounts to all high fidelity printing styles to make them more affordable. For Engineering Service Requests, we charge for raw materials, machine consumables, and for labor.