Text content

Fischer Engineering Design Center

FEDC Resources

The SuSu and Mark A. Fischer ’72 Engineering Design Center (FEDC) Mission Statement

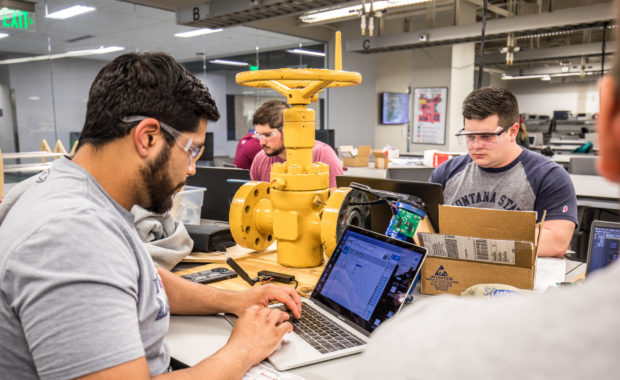

The SuSu and Mark A. Fischer ’72 Engineering Design Center (FEDC) is a space where undergraduate engineering students have access to state-of-the-art prototyping tools, equipment, materials, and support staff to complete their academic projects.

Creativity is accelerated through a combination of imagination, ability, space, tools and materials. It is enhanced by having a place where ideas can be tested, refined and tested again as rapidly as possible. Having the right tools and materials readily available allows students to build amazing creations that expand the realms of possibility.

Through partnerships with industry and non-profit sponsors, the center is an environment where concepts become solutions to real-world problems and student teams come together to build new prototypes, acquire new skills and develop new relationships. It is supported with differential tuition funds and it is open to engineering undergraduate students.

The FEDC is an exclusive academic makerspace for undergraduate engineering students that focuses on three principles:

- Learn: Popup classes offer hands-on instruction where students can learn how to access and operate equipment, tools, and software.

- Design: With an extensive software array and staff trained to assist in many disciplines, we help students in all stages of the engineering design process.

- Build: Spaces to build your project from start to finish, including worktables, electrical workbenches and open floor space, as well as tools, fasteners, power and other utilities.

Our state-of-the-art prototyping tools, equipment and staff support students as they create and invent. This facility offers a full-fledged machine shop, 3D printing, pop-up classes, and design support.

Programs Supported by the Fischer Engineering Design Center:

- Engineering Project Showcase: This event features the work developed by approximately 600 engineering teams. These include departmental capstone design and multidisciplinary team projects of all undergraduate levels and faculty representation from each engineering department.

- Aggies Invent: Aggies Invent is a 48-hour intensive design experience in which students in multidisciplinary teams push their innovation, creativity and communication skills. Each event has a specific theme and is designed in collaboration with industry and faculty. Teams compete for cash awards and the best innovation.

- Competition Teams: Competition teams provide students with great opportunities to apply their engineering skills in solving real-world problems as part of a multidisciplinary team, while competing with the best teams across the nation. As space is limited in the FEDC all housed and FEDC affiliated teams are subject to approval through our team account request form.

- Pop-Up Classes – The Fischer Design Center offers pop-up classes in fabrication, prototyping, electronics, programming, and communications. In-person Pop-Up Classes require attendees to be an approved member of the FEDC.

FEDC Academic Policy

The FEDC was developed to provide a space for undergraduate engineering students to build projects, learn new skills, and consult with subject matter experts. It is a strictly academic facility with its share of safety and process rules.

We highly encourage students to get proper training and come into the FEDC and do all manual work themselves. We have trained staff on hand to assist with any point of the process.

FEDC members can register their academic teams and receive a ‘team account PIN number’ which then allows them to submit requests for trained staff to create parts needed for their student projects.

Graduate students and departmental research personnel gain access to the facility through our Engineering Service Center. For rates and access, email [email protected]

Design Studio

The Project Design Studio is a multidisciplinary small build and large build space.

We provide tabletop, floor space, lockers and other storage available for reservation for up to semester long use.

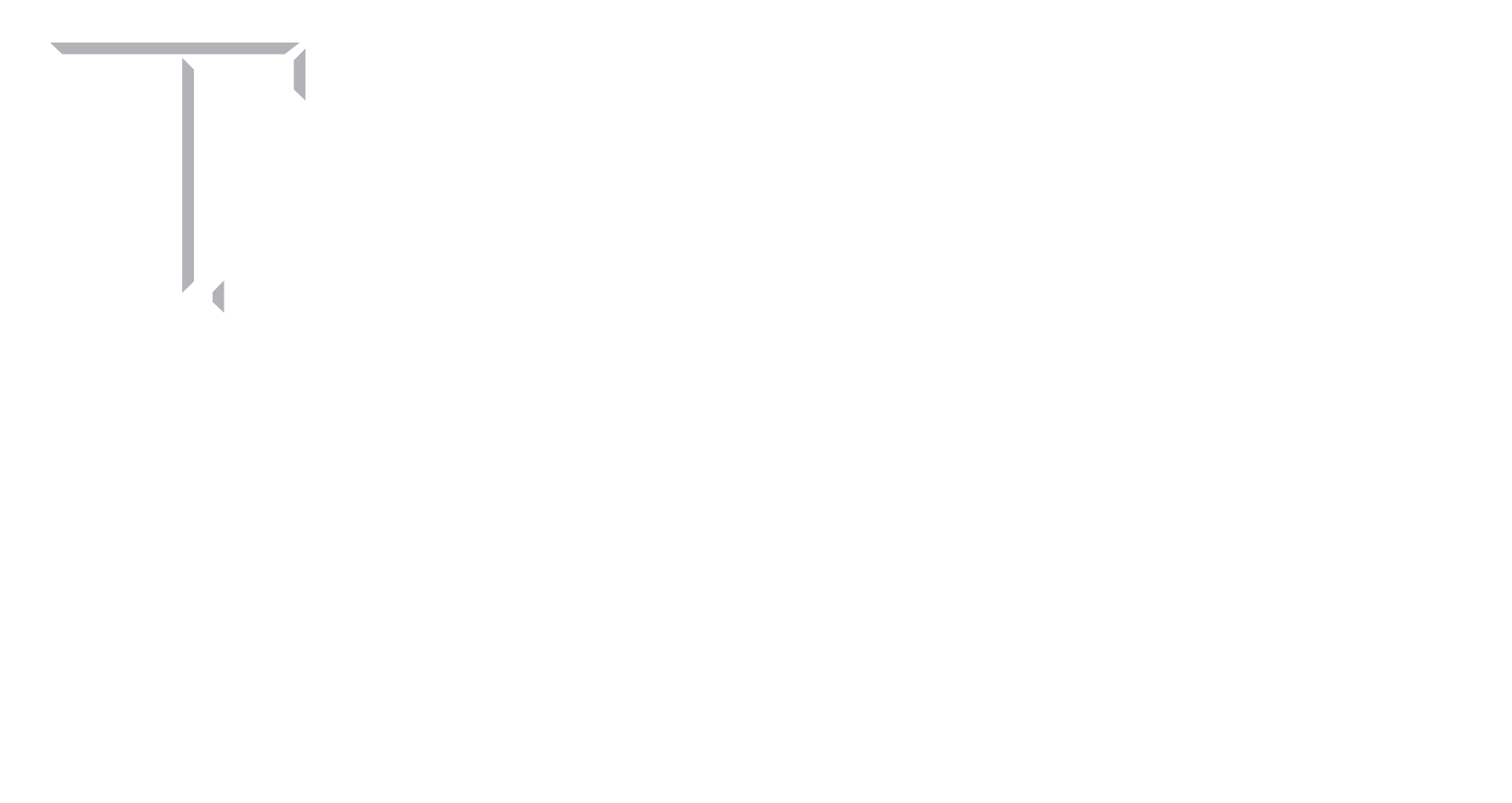

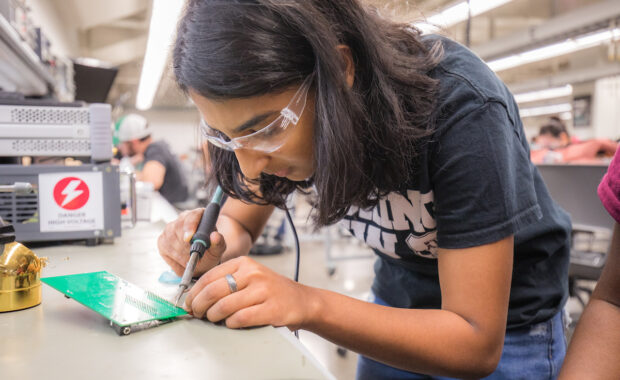

We offer stations for 3D low fidelity printing, a sewing machine, weight and measurement equipment, soldering and electronic stations, and a large construction zone for using hand tools.

General Membership is required to gain access

Fabrication Center

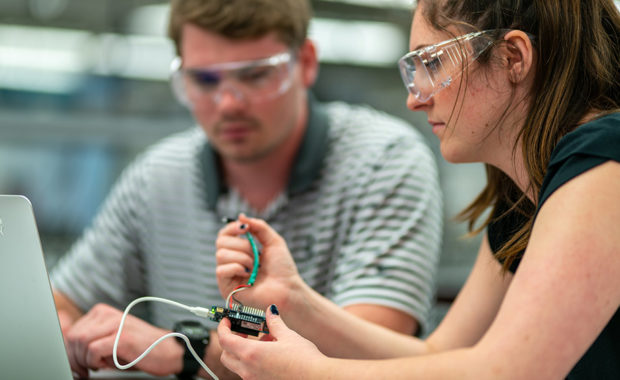

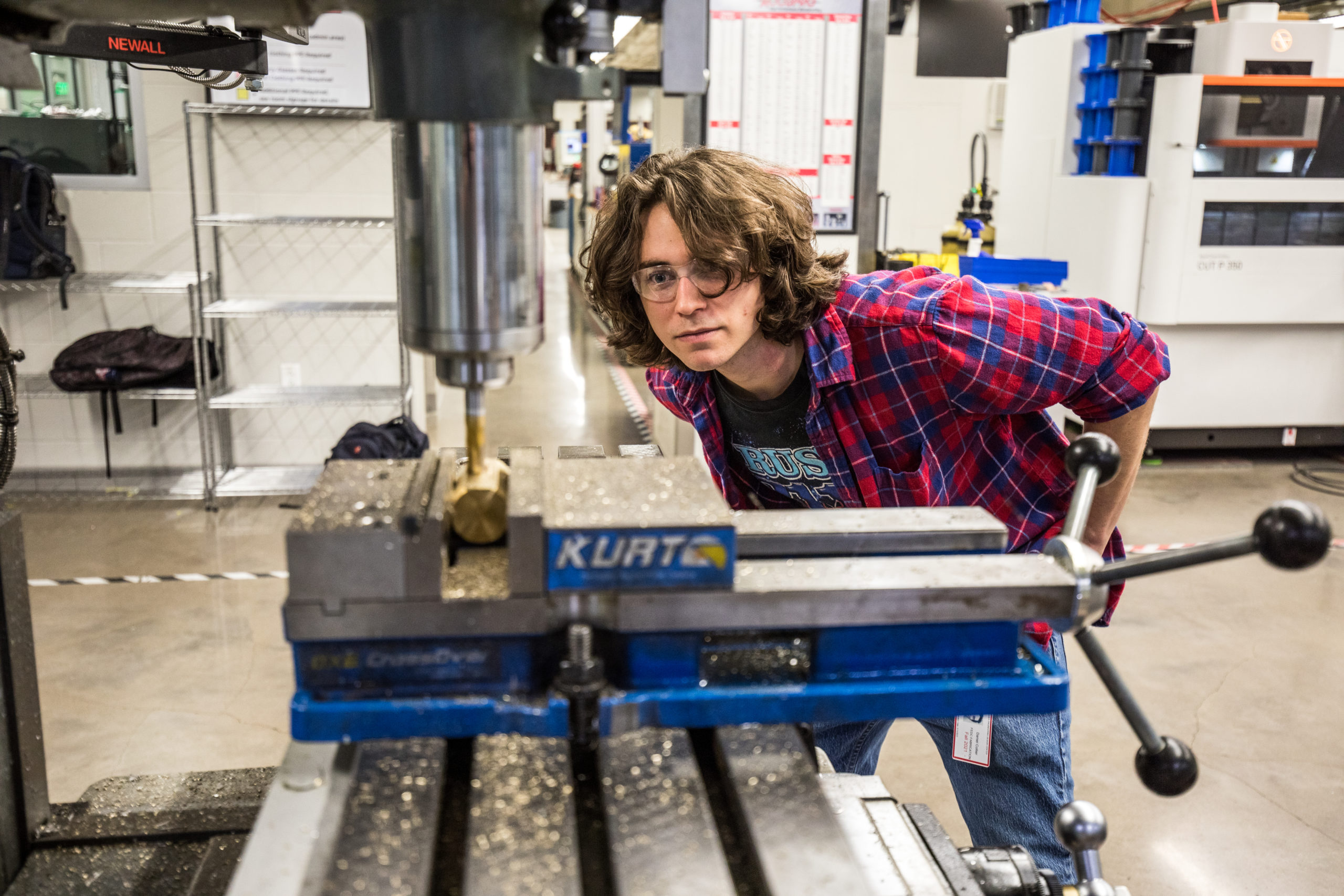

The Fabrication Center is a full-featured machining and computer numerical control (CNC) resource.

Our goal is to provide a space where students come to learn, design, and build their own parts. We provide training and onsite assistance.

Areas offered by the Fabrication shop: Manual Mils, lathes, saws, and hand tools, and CNC mils, lathes, EDM, grinders, water jet, foam cutting, composites, and injection molding.

General Membership and a Red Badge is required to gain access.

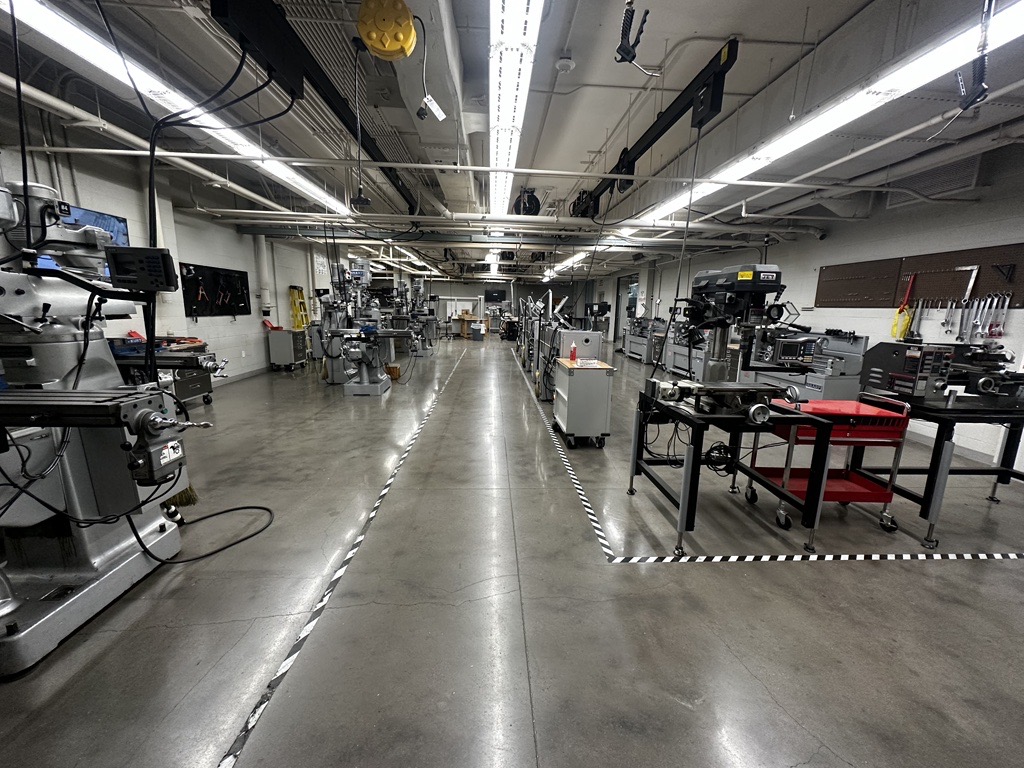

Lab Instructional Space

The Lab Instructional Space was created to accommodate undergraduate fabrication labs such as MEEN 361 and ISEN 281 to provide a collaborative space where engineering course laboratories can meet and learn together.

The Lab Instructional Space is comprised of 6 new manual mils and lathes as well as an adjustable-height mill and lathe for accommodating special circumstances.

When courses are not in session this space serves as an overflow to help all the students complete all their academic projects on time.

Prototyping Center

The Prototyping Center has the capacity to print in plastic, metal, and resin using more than 30 desktop to industrial grade 3D printers. We also offer laser cutting for woods/plastics, and can make prototype circuit boards in-house.

All prototyping requests are submitted through our service request form that can be found under the Services tab.

For a description of the printing technologies and materials available please visit our 3D printing FAQ.

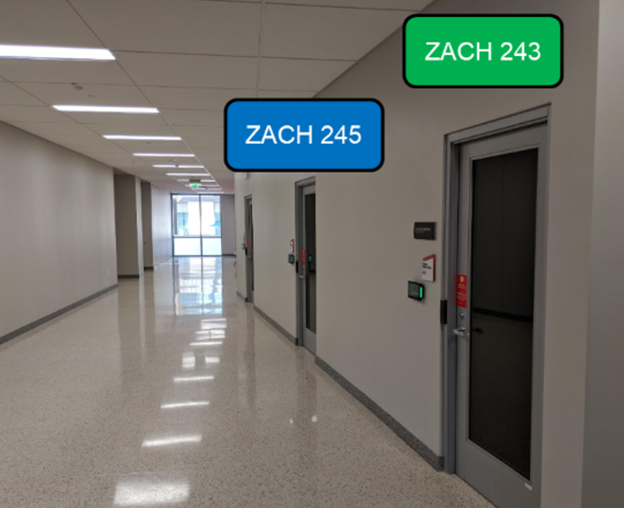

Digital Production Media Rooms

The FEDC controls two media rooms on the second floor for students to record presentations. These rooms come complete with full audio and video recording equipment and even have drop-down blue or green screens for interactive presentations.

Reservations for the Digital Production Media Rooms are made through our Zachry Labs Scheduling page.

FEDC General Membership is required, and students must pass the FEDC Digital Production pop-up class to reserve the rooms.

Personal Protective Equipment

The FEDC has a a basic PPE standard requirement across all sections of the center.

Why?

Here at the FEDC we are committed to:

- The safety of our students and staff

- Preparing our engineering students for industry expectations

General Shop safety training is provided through our Red Badge Pop-up class. Machine-specific trainings are provided through associated Pop-Up classes.

Work areas will need to be kept neat and should be cleaned up after use.

The FEDC operates on a zero-tolerance policy when it involves safety violations. Non-compliance with safety expectations will result in consequences according to FEDC/TAMU policy

Staff

We are here to help you

The FEDC employs 8 full time staff and over 40 trained student workers across the facility who are here to aid engineering students with their many academic projects.

Our full time staff we offers over 100 years of professional machining and engineering education experience.

Schedule a consultation

Walk ups are welcome, however not guaranteed.

To meet with one of our professionals for consultation on a project, please email [email protected]

Include the following information:

- Who would you like to talk to?

- What class your project is for?

- When you are able to meet? (multiple options)

- Details about your project including attachments.

Differential tuition pays for enhancements to the learning experience of undergraduate students in engineering. These enhancements include extra sections of overfull courses, new computers and equipment, and even extra lecturers to teach classes. Learn more about differential tuition.