Low Fidelity Machines

All are FDM-style machines which extrude plastic filament through a heated nozzle to build the part layer by layer. Primary material is PLA, but can also use ABS, PETG, TPU, Nylon, etc. With Engineering Justification. CreatBot can print with higher temperature materials (ULTEM 9085).

Ultimaker S5

Printer Specifications

Material: PLA

Support: breakaway

Build Volume: 330x240x300mm (13×9.4×11.8in)

Z slice: 20-200 micron – FEDC default is 200 microns

Bead width: 0.4mm nozzle

Accuracy/Resolution: 6.9 microns in XY, 2.5 microns in Z

FEDC default settings: Infill at 15%

Software: Ultimaker Cura

Prusa XL

Printer Specifications

Material: Primary materials are PLA and PETG; can use others (With Engineering Justification)

Support: breakaway

Build Volume: 360x360x360mm (14.17×14.17×14.17in)

Z slice: 50-300 micron – FEDC default is 200 microns

Toolhead: Single extruder/toolhead

Bead width: 0.4mm nozzle

Accuracy/Resolution: 20 microns in XY, 10 micron in Z

FEDC default settings: Infill at 15%

Software: OrcaSlicer

BambuLabs X1-Carbon

Printer Specifications

Materials: Primary materials are ABS, TPU, and PETG; can also use PLA, Nylon, etc. (With Engineering Justification)

Support: breakaway

Build Volume: 256x256x256mm (10x10x10in)

Z slice: 80 microns to 280 microns – FEDC default is 200 microns

Bead width: 0.4mm nozzle

Accuracy/Resolution: ±0.2 to 0.5 mm

FEDC default settings: Infill at 15%

Software: OrcaSlicer

MakerBot Method X

Printer Specifications

Material: Used for larger ABS prints (With Engineering Justification)

Support: breakaway

Build Volume: 152 x 190 x 196mm (7.5 x 7.5 x 7.75in)

Z slice: 20-400 microns – FEDC default is 200 microns

Bead width: 0.4mm nozzle

Accuracy/Resolution: +/- 0.2 mm dimensional accuracy

FEDC default settings: 3 shell layers, infill at 15%

Software: MakerBot Print

CreatBot F430

Printer Specifications

Material: ULTEM 9085, ABS, etc. – (Mean for Higher Temperature Materials)

Support: breakaway

Build Volume: 400 x 300 x 300 mm

Z slice: 0.2mm

Bead width: 0.4mm nozzle

Accuracy/Resolution: XY 12.7μm, Z 1.25μm

FEDC default settings: Infill at 15%

Software: PrusaSlicer

Dremel 3D45

Yellow Badge Only!

Printer Specifications

Material: PLA

Support: breakaway

Build Volume: 255x155x170mm (10x6x6.7in)

Z slice: 50-300 microns, FEDC default is 200 microns

Bead width: 0.4mm nozzle

Accuracy/Resolution: generally within 0.1mm

FEDC default settings: infill at 15%

Software: Dremel DigiLab

High Fidelity Machines

FDM Style Machines

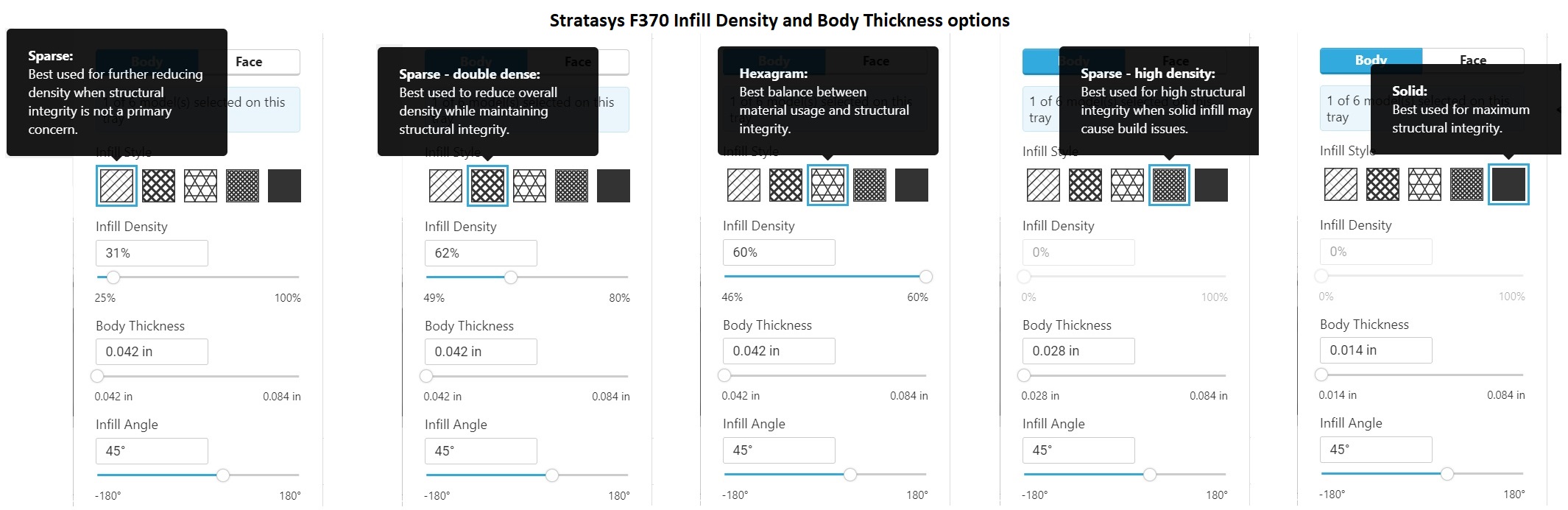

STRATASYS F370

Printer Specifications

Material: ABS, ASA, PC-ABS, ABS-CF10, TPU – (Future possibilities include: ABS-ESD7 and Diran)

Support: Soluble

Build Volume: 355 x 254 x 355 mm (14 x 10 x 14 in.)

Z slice: 0.005-0.013in – FEDC default is 0.01in

Bead width: 0.25mm for 0.01in Z slice

Accuracy/Resolution: Parts are produced within an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in), whichever is greater.

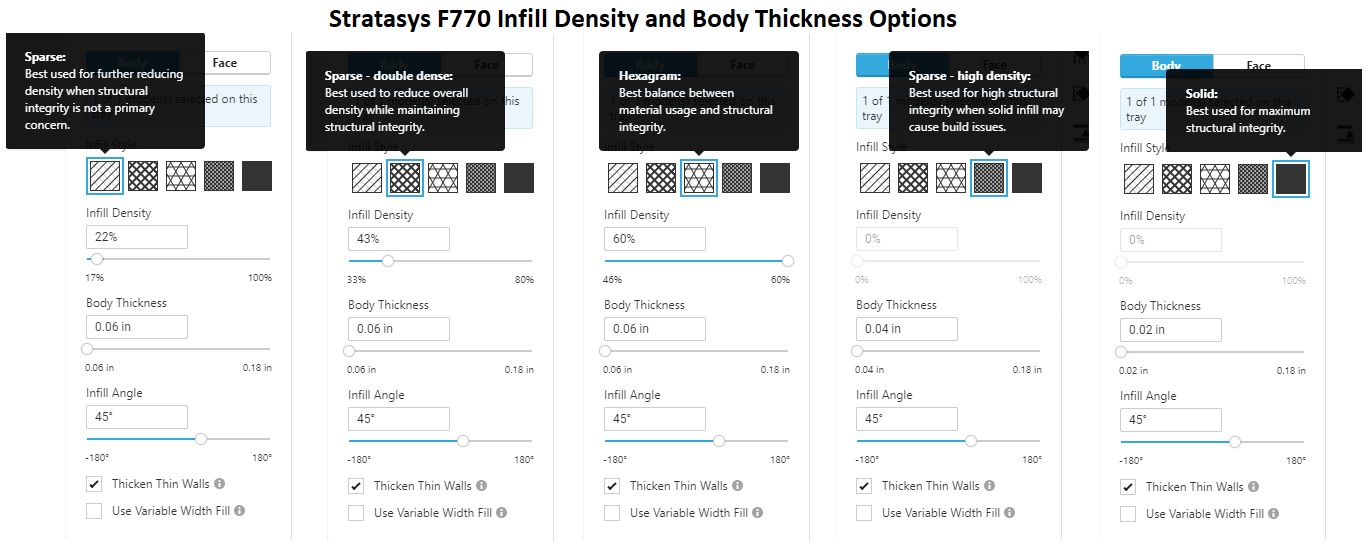

FEDC default settings: Sparse – High Density Infill with 0.04in Body Thickness

Software: GrabCAD

Essentium HSE 180-S

Printer Specifications

Material: PCTG and High Temperature Nylon – (other lower temperature filaments may be possible)

Support: breakaway

Build Volume: 690 x 500 x 600 mm (27.1×19.7×23.6in)

Z slice: 0.25mm

Bead width: Nozzle Diameters: 0.4, 0.8 mm (FEDC Default 0.4mm)

Accuracy/Resolution: XY < 30μm, Z < 5μm

FEDC default settings: Varies greatly by part. Many parts require redesign to print successfully

Stratasys F770

Polyjet Style Machines

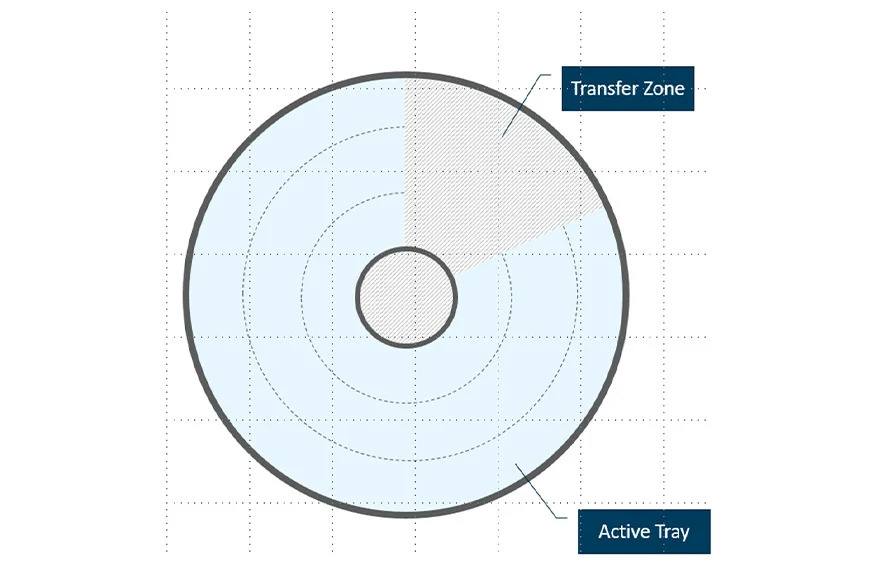

Stratasys J55

Printer Specifications

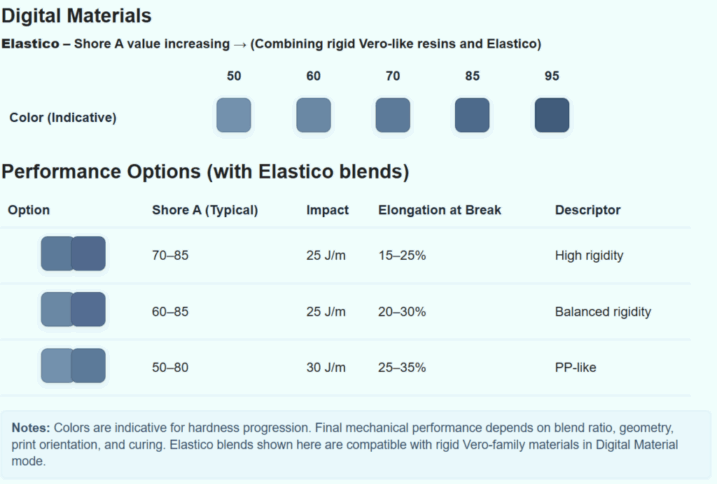

Material: acrylic-like VeroColor suite, Clear, DraftGrey, VeroContact, and rubber-like Elastico

Support: water-soluble

Build Volume: 140 x 200 x190 mm (5.5 x 7.8 x 7.5 in)

Z slice: 18.75 microns

Bead width: X 300 dpi, Y 300 dpi, Z 878 dpi (X 42 microns, Y 42 microns, Z 32 microns)

Accuracy/Resolution: for models printed with rigid materials, based on size: under 100 mm – ±150μ; above 100 mm – ± 0.15% of part length, whichever is greater

FEDC default settings: Dependent upon part needs. Infill is 100%

Software: GrabCAD Print Pro

SLA Style Machines

Cure resin with a light/laser beam to build the part layer by layer. Materials available are Grey and Clear, with different engineering grade materials to be made available upon need.

Formlabs Form 4

Printer Specifications

Material: Primary materials are Grey and Clear. Materials such as Silicone 40A, High Temp Resin, and Rigid 10k are subject to availability. Other engineering materials available with engineering justification and minimum use requirements.

Support: breakaway

Build Volume: 200×125×210mm (7.9 × 4.9 × 8.3 in)

Z slice: 25-200 microns – FEDC default is 50-100 microns

Bead width: laser spot size 50 micron pixel size

Accuracy/Resolution:

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.2% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

FEDC default settings: Dependent upon part needs, Infill is 100%

Software: Preform

Formlabs Form 2 (deprecated)

Printer Specifications

Material: Grey and Clear. Other engineering materials available with engineering justification and minimum use requirements

Support: breakaway

Build Volume: 145×145×175mm (5.7 × 5.7 × 6.9 in)

Z slice: 25-300 microns – FEDC default is 50-100 microns

Bead width: laser spot size 140 microns ~150 micron bead size

Accuracy/Resolution: 95% of prints measured within 0.240mm of designed part

FEDC default settings: Dependent upon part needs, Infill is 100%

Software: Preform

Printer Circuit Board Equipment

Using the Protomat S103 as a CNC router, we are able to create copper traces on boards to create a prototype circuit board. We do not do thru-hole plating.

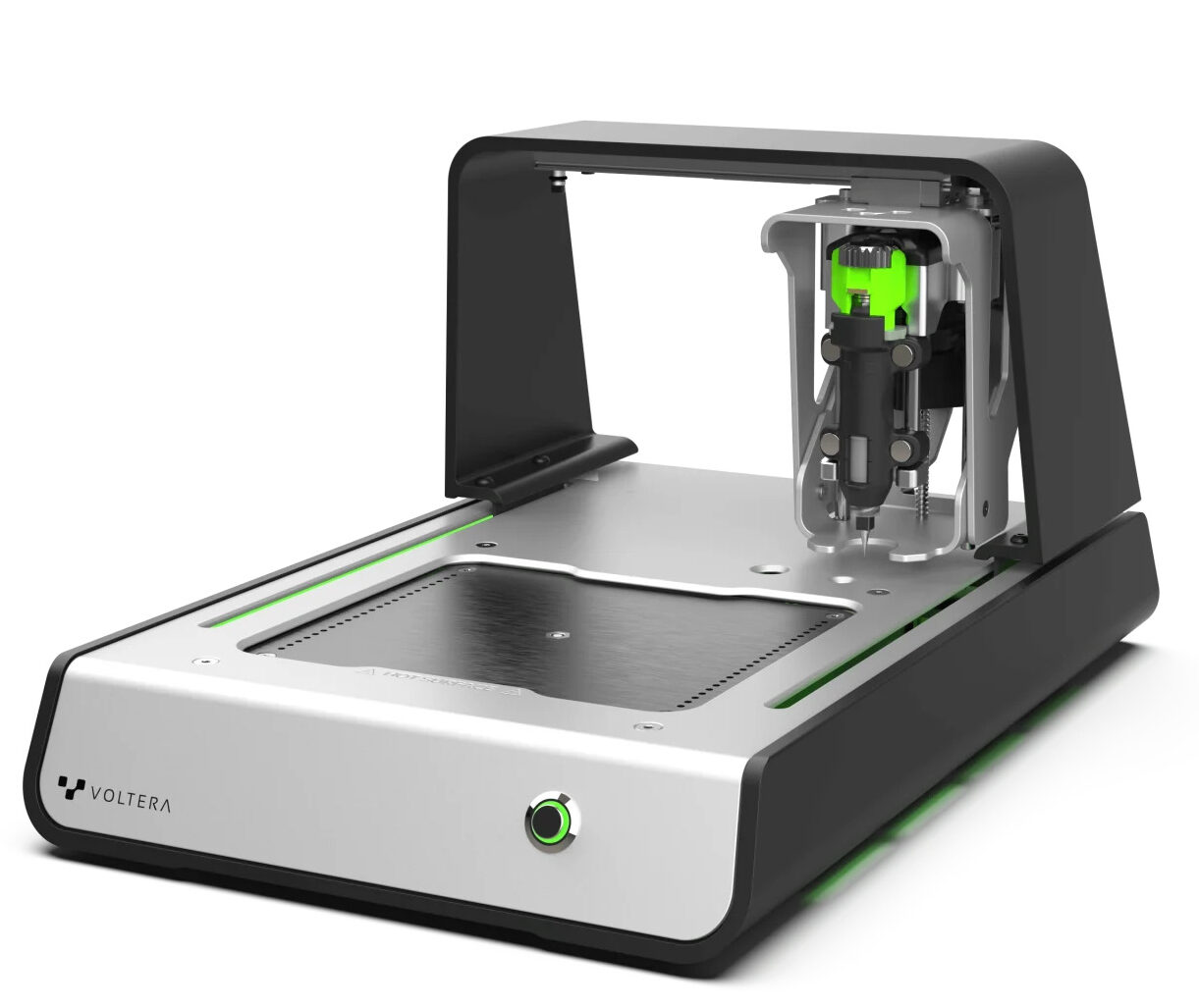

Voltera V-One

Basic Specifications

File format: Gerber

Dispensing technology: Direct ink write (DIW)

Minimum trace width: 0.2 mm

Print area: 128 mm x 116 mm x 3 mm

XYZ resolution*: 10 µm x 10 µm x 1 µm

Substrates: Rigid: FR1 and FR4

Dispensable materials: Solder paste and Conductor 3

Additional features: Integrated hot plate for cure and reflow soldering

* – XYZ accuracy is +/- 20 µm

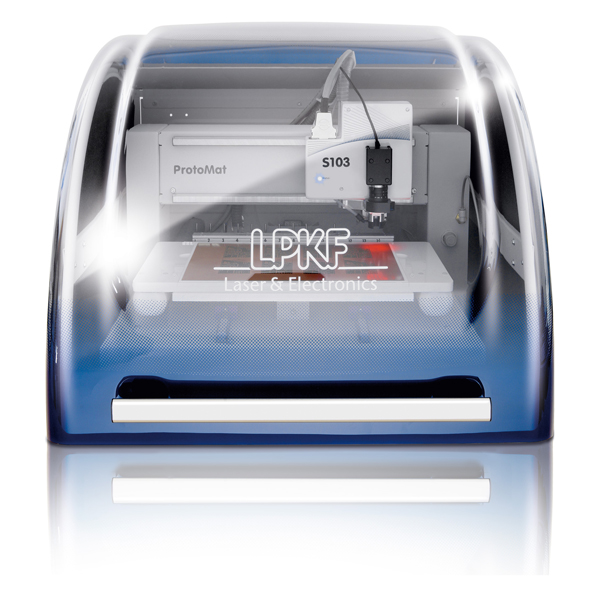

Protomat S103

Basic Specifications

Max. material size and layout area (X/Y/Z): 229 mm x 305 mm x 35/22 mm (9” x 12” x 1.4/0.9”)*

Resolution (X/Y): 0.5 μm (0.02 mil)

Repeatability: ± 0.001 mm (± 0.04 mil)

Precision of front-to-back alignment: ± 0.02 mm (± 0.8 mil)

Milling spindle Max: 100,000 rpm

Tool holder: 3.175 mm (1/8”)

Drilling speed: 120 strokes/min

Travel speed (X/Y) Max: 150 mm/s (6”/s)

Minimum Drill Size: 0.2mm

Standard boards may have minimum 1.0 mm trace thickness and 2.0 mm spacing; anything less requires justification and will result in additional manufacturing time and cost.

No text or images

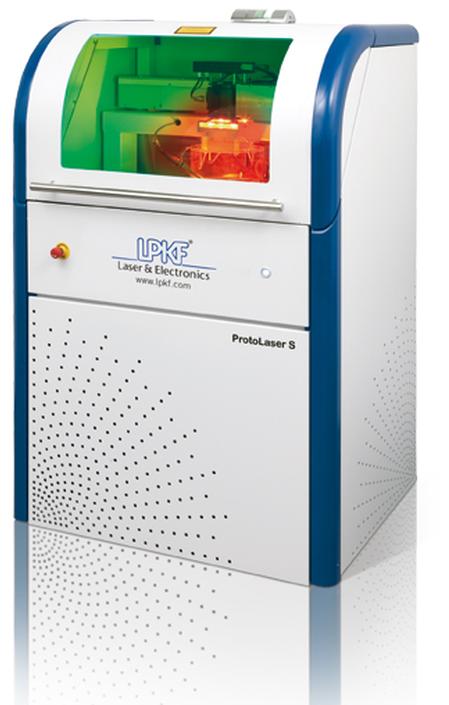

Protolaser S – CURRENTLY OUT OF SERVICE

Laser Cutting Equipment

The ILS9.75 is a free-standing platform with a materials processing envelope of 36” x 24” x 12” or 10,368 in³ (914 x 610 x 305 mm or 169,901 cm³). This is a CO2 laser.

Universal Laser System ILS 9.75

Vinyl Cutting Equipment

The LP801 is a model number primarily associated with the USCutter LaserPoint II 801 vinyl cutter. It is a stepper-motor cutter designed for professional sign-making and graphic arts projects, offering a balance of performance and value.